Milbay LiFePO4 Battery Solutions for Electric Golf cars

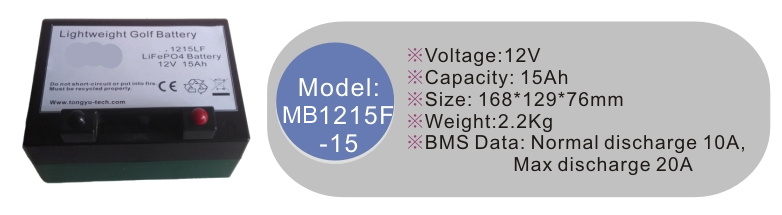

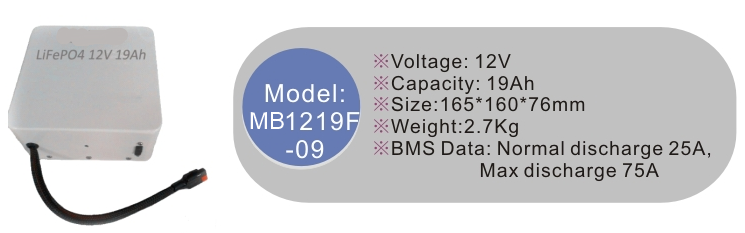

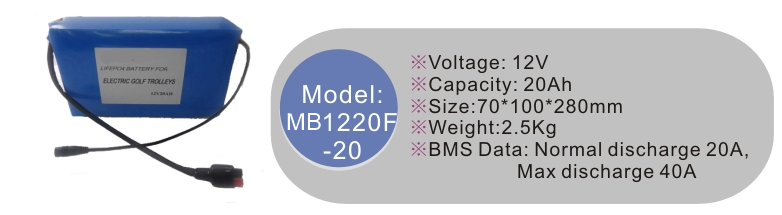

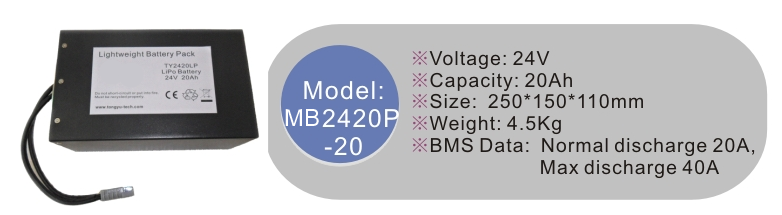

Milbay supply a large range of standard and custom LiFePO4 battery solutions to improve the power, travel distance and remove the need for user maintenance of electric golf car battery systems.

Retail and wholesale enquiries are welcome. Contact us or Send an online Enquiry to Milbay .

LiFePO4 Advantages

-

Up to 5 times lighter than traditional lead-acid batteries.

-

Approximately 20% more power.

-

Latest development in LiFePO4 (Lithium Ferrous Phosphate) chemistry.

Stable Long working life - 5 to 10 Years - 1500 + recharge cycles.

Integrated BMS (Battery Management System) for overcharge protection, individual cell power output and recharge control.

Completely maintenance free.

Zero liquid or GEL corrosives

Zero corrosive gases

Excellent power to weight density.

Holds charge for more than twice as long as lead-acid batteries.

-

Delivers full power untill almost completely discharged.

Environmentally friendly, Recyclable, ROHS (Removal of Harmful Substance) Compliant.

Lead-Acid Battery Disadvantages

Short life.

Heaviest material, Pb Lead.

Delivers only 30% - 70% of battery capacity.

Old technology.

Requires maintenance.

NO Battery Management System.

Low efficiency.

Low return on investment.

Most expensive option over the devices lifespan, LiFePO4 power cells last 5 to 10 times longer.

More environmentally damaging.

Contains corrosive acid.

Connectors

Milbay supply LiFePO4 batteries with many different types of standard and custom connectors to match the original golf car electrical system to ensure easy installation and standardisation.

SB50 Power Connector

Charging

Depending on the particular golf car brand and model you may or may not require a new charger for your Milbay LiFePO4 battery system. After looking at the specifications of your current charger our specialist technicians will be able to advise if a new charger will be required to match your new custom Milbay LiFePO4 battery system.

NOTE:

Some Lead-acid battery chargers will not be suitable for recharging Milbay LiFePO4 batteries.

FAQs - Frequently Asked Questions about LiFePO4, Lithium Ion and LIPO

FAQs - Frequently Asked Questions about LiFePO4, Lithium Ion and LIPO

How to care for your lithium battery and Charger

How to care for your lithium battery and Charger

Always store any lithium type battery (LIPO - Polymer, LiIon - Lithium Ion, LFP - LifePO4 Lithium Ferrous Phosphate) with a full charge and batteries should be recharged every 3 months.

Recharging

Recharge your lithium battery after every use regardless of the level of discharge ie. how much the battery has been drained during use. Lithium batteries will last longer and provide better power output if recharged after every use, the more shallow the Depth Of Discharge (D.O.D) the greater the recharge cycles.

Chargers

Most lithium batteries will last over three years if correctly maintained so it is recommended that a new charger is purchased along with a replacement battery. Each lithium battery type requires a charger that uses the correct charging method and voltage to safely charge the battery pack and provide the longest battery life.

Improvements to battery charger electronics and design may also have occurred in the time since the first charger was purchased.

Most common reason for charger failure.

A failed fan in chargers (that use a fan) is the most common reason for charger failure which can increase the chance of damage to the Lithium battery pack. The fans in the battery chargers have a limited life so repair or replace any charger that has a failed fan.

Charger electrical compliance.

Chargers that plug into the normal 240V power outlets sold in Australia must meet Australian electrical compliance, generally this is indicated by the C Tick logo or the new Single Compliance mark, as shown in image below.

What does the C rating on a Lithium battery pack mean ?

What does the C rating on a Lithium battery pack mean ?

The C rating is the maximum safe continuous discharge rate of a battery pack.

10C means the battery pack can be discharged at 10 times that pack's capacity.

The Capacity rating of the battery pack is generally shown in milliamp hours, a milliamps is equal to 1/1000 of an amp.

The battery pack capacity rating will be printed on the battery pack or outer case as a number followed by mAh

Example : 2000mAh, which is equal to 2.0 Ah.

To find your battery's discharge rate multiply the number from the C rating by the pack's capacity.

Here is a calculation example using an 60V 22000mAh 10C (Electric unicycle battery pack)

Details from battery pack label : 60 volt 2200mAh -10C

2200 milliamps = 2.2 amps

2.2 Amps x 10 = 22 amps continuous discharge

Result : The 60V 2200mAh 10C battery pack can safely draw up to 22 amps continuously without causing a problem.

The cell will also have a peak value that is applicable for a few seconds or short period of maxium motor load where the motor power will peak.

What is a 'Wh' Rating, why use it to calculate power capacity ?

What is a 'Wh' Rating, why use it to calculate power capacity ?

A simply explaination of work is how many kilometers can be travelled on a electric bicycle or how long a solar power storage unit could keep a fridge running for at night.

A 12V 10 Ah Lithium Ion bicycle battery would be calculated as 4 (number of cells in series) x 3.7V (nominal cell volatge) = 14.8V x 10000Mah - 10Ah (capacity of each cell) = 148Wh

A 60V 2.2 Ah Lithium Ion unicycle battery would be calculated as 16 (number of cells in series) x 3.7V (nominal cell volatge) = 59.2V x 2200Mah - 2.2Ah (capacity of each cell) = 130Wh

Are there different types of Lithium battery packs, what are the differences ?

Are there different types of Lithium battery packs, what are the differences ?

LiFePO4 Safety

LiFePO4 Safety

It is commonly accepted that LiFePO4 battery does not decompose at high temperatures.

How long is the warranty on LiFePO4 batteries ?

How long is the warranty on LiFePO4 batteries ?

Electrical Calculations

Electrical Calculations

A history of Battery Developement

A history of Battery Developement

|

Year

|

Inventor

|

Activity

|

|

1600

|

William Gilbert (UK)

|

Establishment of electrochemistry study

|

| 1745 | Ewald George von Kleist (Netherlands) | Invention of Leyden jar. Stores static electricity |

|

1791

|

Luigi Galvani (Italy)

|

Discovery of “animal electricity”

|

|

1800

1802

1820

1833

1836

1839

1859

1868

1899

|

Alessandro Volta (Italy)

William Cruickshank (UK)

André-Marie Ampère (France)

Michael Faraday (UK)

John F. Daniell (UK)

William Robert Grove (UK)

Gaston Planté (France)

Georges Leclanché (France)

Waldmar Jungner (Sweden)

|

Invention of the voltaic cell (zinc, copper disks)

First electric battery capable of mass production

Electricity through magnetism

Announcement of Faraday’s law

Invention of the Daniell cell

Invention of the fuel cell (H2/O2)

Invention of the lead acid battery

Invention of the Leclanché cell (carbon-zinc)

Invention of the nickel-cadmium battery

|

|

1901

1932

1947

1949

1970s

1990

1991

1994

1996

1996

|

Thomas A. Edison (USA)

Shlecht & Ackermann (D)

Georg Neumann (Germany)

Lew Urry, Eveready Battery

Group effort

Group effort

Sony (Japan)

Bellcore (USA)

Moli Energy (Canada)

University of Texas (USA)

|

Invention of the nickel-iron battery

Invention of the sintered pole plate

Successfully sealing the nickel-cadmium battery

Invention of the alkaline-manganese battery

Development of valve-regulated lead acid battery

Commercialization of nickel-metal-hydride battery

Commercialization of lithium-ion battery

Commercialization of lithium-ion polymer

Introduction of Li-ion with manganese cathode

Identification of Li-phosphate (LiFePO4)

|

|

2002

|

University of Montreal, Quebec Hydro, MIT, others

|

Improvement of Li-phosphate, nanotechnology, commercialization

|

How to care for your lithium battery and Charger

How to care for your lithium battery and Charger

Always store any lithium type battery (LIPO - Polymer, LiIon - Lithium Ion, LFP - LifePO4 Lithium Ferrous Phosphate) with a full charge and batteries should be recharged every 3 months.

Recharging

Recharge your lithium battery after every use regardless of the level of discharge ie. how much the battery has been drained during use. Lithium batteries will last longer and provide better power output if recharged after every use, the more shallow the Depth Of Discharge (D.O.D) the greater the recharge cycles.

Chargers

Most lithium batteries will last over three years if correctly maintained so it is recommended that a new charger is purchased along with a replacement battery. Each lithium battery type requires a charger that uses the correct charging method and voltage to safely charge the battery pack and provide the longest battery life.

Improvements to battery charger electronics and design may also have occurred in the time since the first charger was purchased.

Most common reason for charger failure.

A failed fan in chargers (that use a fan) is the most common reason for charger failure which can increase the chance of damage to the Lithium battery pack. The fans in the battery chargers have a limited life so repair or replace any charger that has a failed fan.

Charger electrical compliance.

Chargers that plug into the normal 240V power outlets sold in Australia must meet Australian electrical compliance, generally this is indicated by the C Tick logo or the new Single Compliance mark, as shown in image below.

What does the C rating on a Lithium battery pack mean ?

What does the C rating on a Lithium battery pack mean ?

The C rating is the maximum safe continuous discharge rate of a battery pack.

10C means the battery pack can be discharged at 10 times that pack's capacity.

The Capacity rating of the battery pack is generally shown in milliamp hours, a milliamps is equal to 1/1000 of an amp.

The battery pack capacity rating will be printed on the battery pack or outer case as a number followed by mAh

Example : 2000mAh, which is equal to 2.0 Ah.

To find your battery's discharge rate multiply the number from the C rating by the pack's capacity.

Here is a calculation example using an 60V 22000mAh 10C (Electric unicycle battery pack)

Details from battery pack label : 60 volt 2200mAh -10C

2200 milliamps = 2.2 amps

2.2 Amps x 10 = 22 amps continuous discharge

Result : The 60V 2200mAh 10C battery pack can safely draw up to 22 amps continuously without causing a problem.

The cell will also have a peak value that is applicable for a few seconds or short period of maxium motor load where the motor power will peak.

What is a 'Wh' Rating, why use it to calculate power capacity ?

What is a 'Wh' Rating, why use it to calculate power capacity ?

A simply explaination of work is how many kilometers can be travelled on a electric bicycle or how long a solar power storage unit could keep a fridge running for at night.

A 12V 10 Ah Lithium Ion bicycle battery would be calculated as 4 (number of cells in series) x 3.7V (nominal cell volatge) = 14.8V x 10000Mah - 10Ah (capacity of each cell) = 148Wh

A 60V 2.2 Ah Lithium Ion unicycle battery would be calculated as 16 (number of cells in series) x 3.7V (nominal cell volatge) = 59.2V x 2200Mah - 2.2Ah (capacity of each cell) = 130Wh

Are there different types of Lithium battery packs, what are the differences ?

Are there different types of Lithium battery packs, what are the differences ?

LiFePO4 Safety

LiFePO4 Safety

It is commonly accepted that LiFePO4 battery does not decompose at high temperatures.

How long is the warranty on LiFePO4 batteries ?

How long is the warranty on LiFePO4 batteries ?

Electrical Calculations

Electrical Calculations

A history of Battery Developement

A history of Battery Developement

|

Year

|

Inventor

|

Activity

|

|

1600

|

William Gilbert (UK)

|

Establishment of electrochemistry study

|

| 1745 | Ewald George von Kleist (Netherlands) | Invention of Leyden jar. Stores static electricity |

|

1791

|

Luigi Galvani (Italy)

|

Discovery of “animal electricity”

|

|

1800

1802

1820

1833

1836

1839

1859

1868

1899

|

Alessandro Volta (Italy)

William Cruickshank (UK)

André-Marie Ampère (France)

Michael Faraday (UK)

John F. Daniell (UK)

William Robert Grove (UK)

Gaston Planté (France)

Georges Leclanché (France)

Waldmar Jungner (Sweden)

|

Invention of the voltaic cell (zinc, copper disks)

First electric battery capable of mass production

Electricity through magnetism

Announcement of Faraday’s law

Invention of the Daniell cell

Invention of the fuel cell (H2/O2)

Invention of the lead acid battery

Invention of the Leclanché cell (carbon-zinc)

Invention of the nickel-cadmium battery

|

|

1901

1932

1947

1949

1970s

1990

1991

1994

1996

1996

|

Thomas A. Edison (USA)

Shlecht & Ackermann (D)

Georg Neumann (Germany)

Lew Urry, Eveready Battery

Group effort

Group effort

Sony (Japan)

Bellcore (USA)

Moli Energy (Canada)

University of Texas (USA)

|

Invention of the nickel-iron battery

Invention of the sintered pole plate

Successfully sealing the nickel-cadmium battery

Invention of the alkaline-manganese battery

Development of valve-regulated lead acid battery

Commercialization of nickel-metal-hydride battery

Commercialization of lithium-ion battery

Commercialization of lithium-ion polymer

Introduction of Li-ion with manganese cathode

Identification of Li-phosphate (LiFePO4)

|

|

2002

|

University of Montreal, Quebec Hydro, MIT, others

|

Improvement of Li-phosphate, nanotechnology, commercialization

|